Concrete Mix Design PMXDB Mix 5 Self Consolidating Concrete Thin Topping Slab YouTube

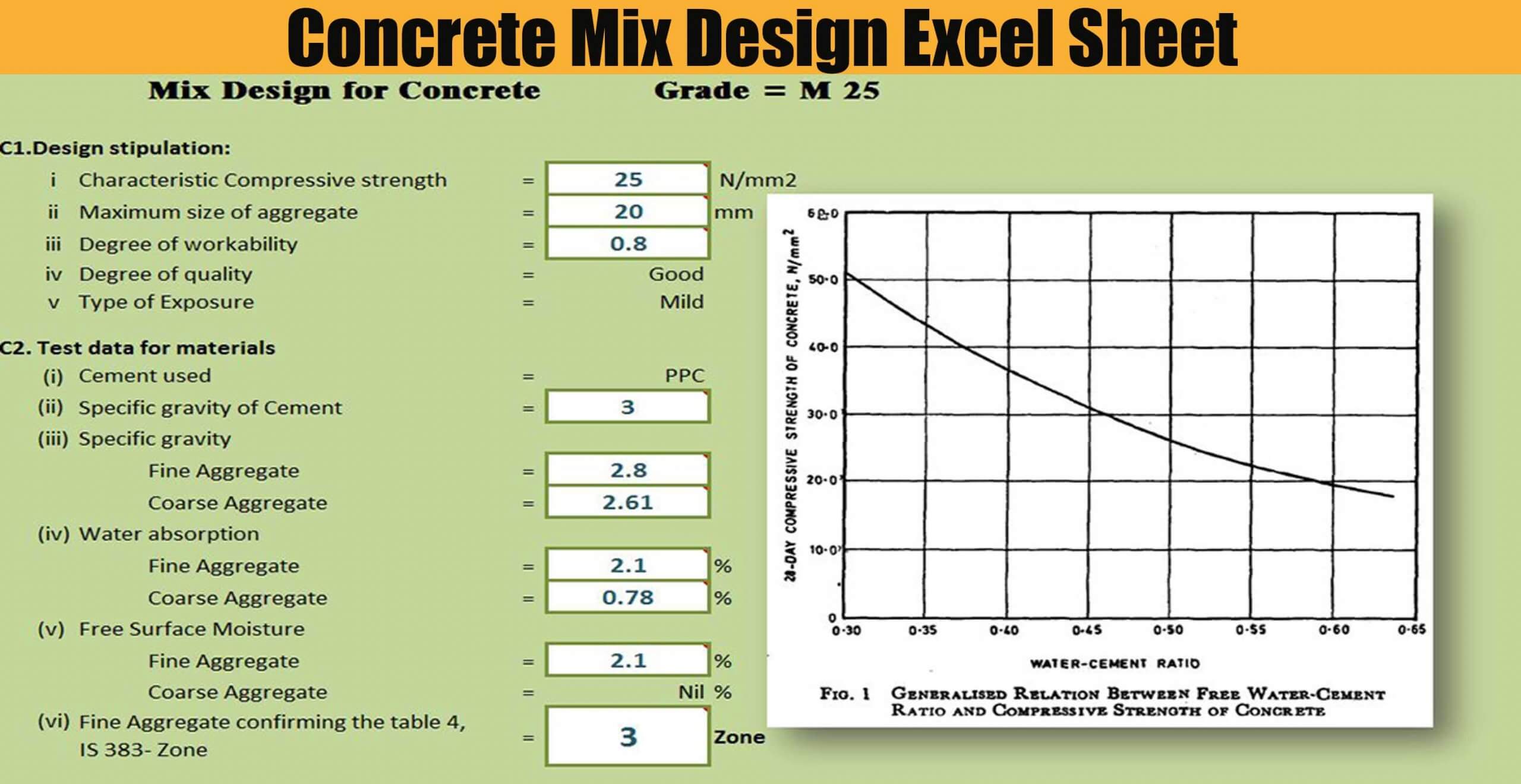

This article presents ACI method of concrete mix design. ACI Method of Concrete Mix Design Required Data: Before starting concrete mix design, basic information on raw materials shall be prepared which include: Sieve analyses of fine and coarse aggregates. Unit weight (dry rodded density) of coarse aggregate.

Concrete Mix Design (AS per ACI code) with Excel Sheets and Software Concrete Mix Ratio

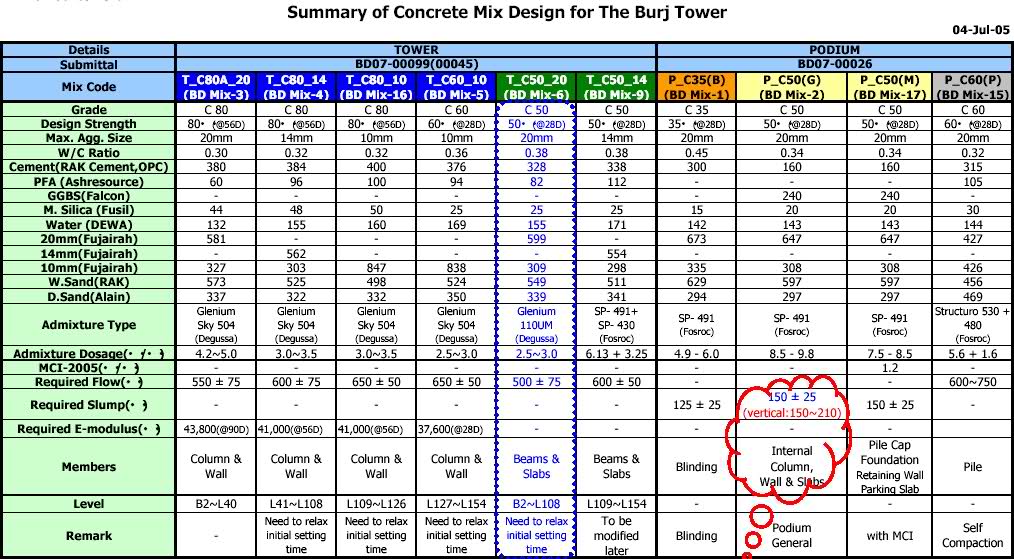

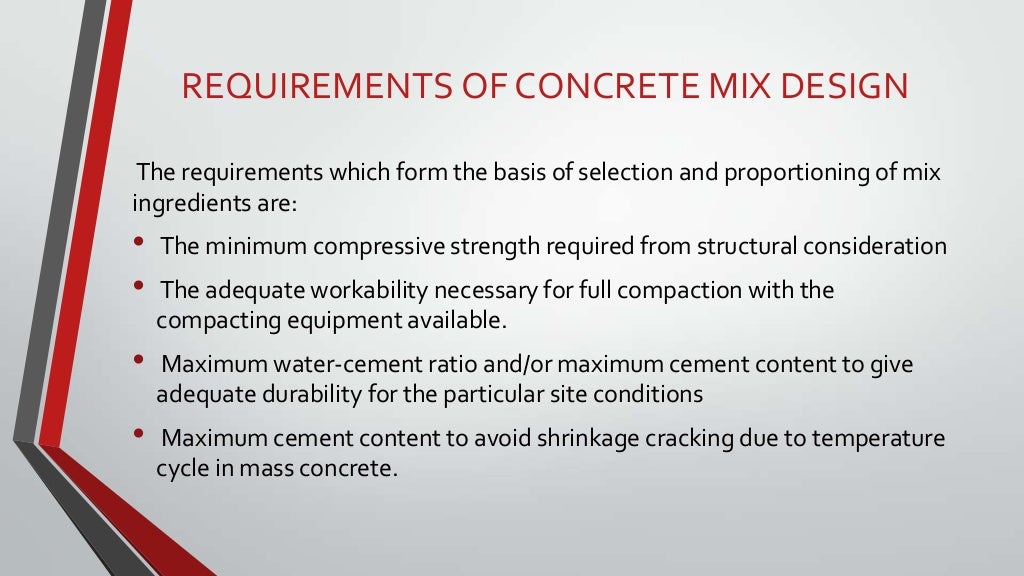

The concrete mix design is performed to ensure that the concrete mix formulation meets or exceeds the specification requirements. The mix design is used to establish the proper proportioning of components (hydraulic cement, aggregates, water, pozzolans, and admixtures) in the mixture to achieve the specified properties..

Civil Engineering Handbook, Engineering Notes, Civil Engineering Design, Mechanical Engineering

The American Concrete Institute (ACI) is a leading authority and resource worldwide for the development and distribution of consensus-based standards, technical resources, educational programs, certification programs, and proven expertise for individuals and organizations involved in concrete design, construction, and materials, who share a commitment to pursuing the best use of concrete.

Concrete Mix Design Concrete is a composite mixture which consists of Cement, Sand and

Winemaking. FERMENTATION: Sauvignon Blanc is fermented in French oak barrels (Vosgues area) 50% from 1 wine and 50% from a 2 wine, Viura and Malvasia fermented in stainless steel. Toasting type Burgundy Medium-High. Temperature controled between 14 and 16º C. Fermented with autochthonous yeast selected from our own vineyards.

Concrete mix ratio Concrete mix design FantasticEng

Mix design is a crucial process in the construction industry that involves determining the proportions and ingredients of concrete to achieve the desired strength, workability, durability, and other properties. It is essential to design a concrete mix that meets the specific requirements of a construction project.

Concrete Mix Design Excel Sheet Engineering Discoveries

Concrete mix design is the methodology for mixing binder, aggregate and water to achieve required physical, mechanical, and thermal properties. In particular, the physical properties depend on the volume fraction of each element in the concrete recipe. In this study we considered cement mortar, complying with ASTM C105, as the reference.

Mix Design of Concrete

Concrete mixes are composed of five major components in various proportions: cement, water, coarse aggregates, fine aggregates (i.e. sand), and air. Chemical admixtures and pozzolanic materials can also be incorporated into the mix to give it certain desired properties. A concrete mix design, on the other hand, is the process of choosing.

Design mix Mix design For all grade concrete YouTube

Basic Concrete Mix Design Materials Pounds of material S.G. Abs Volume 667 3.15 X 62.4 Cement 667 3.15 3.39-Total Cementious 667 Miller Stone 1590 2.6 9.80 Evert Sand 1242 2.65 7.51 Water 300 1 481 1590 2.60 X 62.4 1242 2.65 X 62.4 4.81 Air 5.5% 1.485 Total 3799 27.00 w / cm 0.45 Unit Wt. 140.72 Basic Concrete Mix Design Materials

Mix Design Fundamentals Considerations for concrete for slabsonground Construction Specifier

What is concrete mix design? Why is concrete mix design important? How do factors like exposure conditions influence mix design? What are some common errors in concrete mix design? How does sustainable concrete mix design benefit the environment? Importance of Proper Concrete Mix Design

Changes in Concrete Mix Design Concrete Construction Magazine

Concrete Mix Design Learn the basics of a good concrete mix design By Bill Palmer, Concrete Network Columnist Updated September 17, 2020 Concrete Mix Design Time: 01:02 Learn about which mixes should be used for stamping, staining, and overlays. Just what is concrete mix design?

Concrete mix design Download Scientific Diagram

by Giatec Scientific Inc. June 20, 2023 A concrete mix is a combination of five major elements in various proportions: cement, water, coarse aggregates, fine aggregates (i.e. sand), and air. Additional elements such as pozzolanic materials and chemical admixtures can also be incorporated into the mix to give it certain desirable properties.

Engineered Concrete Mix Design and Test Methods Book Online Civil

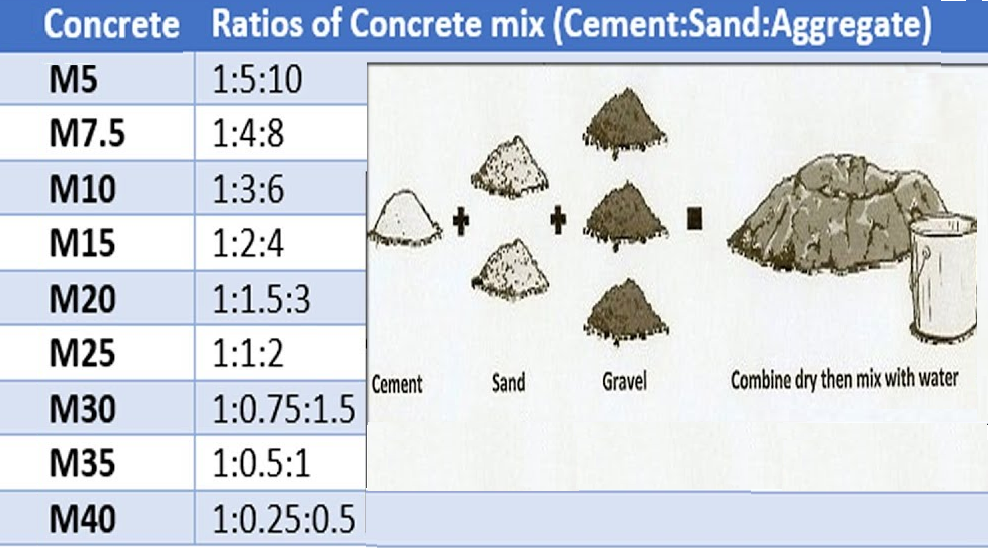

Concrete mix ratios are the proportions of concrete components such as cement, sand, aggregates and water. These mix ratios are decided based on type of construction and mix designs. However, building codes provides nominal and standard concrete mix ratios for various construction works based on experience and testing.

Concrete Mix Design Mix Design of Concrete Concrete Mix Design Calculations YouTube

Design Procedure CONCRETE MIX DESIGN The following describes the Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass concrete based on a report published by the American Concrete Institute (ACI), Committee 211.

Concrete Mix Design M20 Online Civil

Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve target strength in structures. So, concrete mix design can be stated as Concrete Mix = Cement:Sand:Aggregates. The concrete mix design involves various steps, calculations and laboratory testing to find right mix proportions.

ACI Method of Concrete Mix Design Procedure and Calculations

Concrete mix design is the process of selecting suitable ingredients of concrete and determine the relative proportions to produce concrete with certain performance and durability requirements.

Concrete mix design and main concrete properties Download Table

Concrete mix design is the method of determining the correct proportions of cement, fine aggregate (sand), and aggregates for concrete to achieve the target strength of the prepared concrete mix.